Water Treatment

With over 20 years of fluid component design expertise, GloTech leads the way in advanced water treatment technologies. Our products, designed with industry leading hydrodynamic and fluid flow principles, ensure superior efficiency and reliability. From energy-efficient centrifugal pumps to high-performance mixers and aerators, every component is engineered for optimal performance and durability.

GloTech’s commitment to quality and sustainability sets us apart. Our precision-engineered products are built to withstand harsh environments, minimizing energy consumption and environmental impact. We use top-grade materials and a variety of manufacturing processes including four different casting technologies to build every part for success. Choose GloTech for proven expertise, innovative design, and eco-friendly solutions that ensure clean, safe water for a sustainable future.

High Speed Surface Aerators Propellers &

Discharge Cones

At GloTech, we are dedicated to providing innovative and efficient solutions for wastewater treatment. Our most popular offerings, the Aerator Propellers and Aerator Discharge Cones, are designed to enhance the aeration process, ensuring optimal oxygen transfer and mixing within your treatment systems. These products are engineered with precision to meet the rigorous demands of modern wastewater management, helping to maintain environmental standards and operational efficiency. With our Aerator Propellers, you can achieve superior oxygen dispersion, which is crucial for the biological treatment processes. Meanwhile, our Aerator Discharge Cones ensure that the aerated water is effectively distributed, reducing dead zones and enhancing the overall treatment performance.

Our commitment to quality and sustainability drives us to continually innovate and improve our product range. The Aerator Propellers and Aerator Discharge Cones are manufactured using high-grade materials, ensuring durability and long-term reliability even in the most challenging conditions. At GloTech, we understand that every wastewater treatment facility has unique requirements, and our team of experts is ready to work with you to tailor our solutions to meet your specific needs.

Technical Data

- Mixer Sizes: 42”- 100”

- Max. Thrust: 965 lbs

- Max. Speed: 121 rpm

- Max. Power: 10 hp

- Max. Area: 460 ft

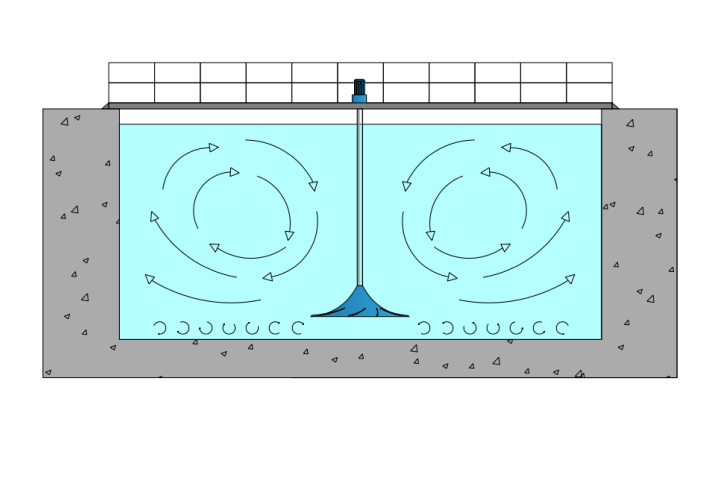

HM-Series Hyperboloid Mixer

GloTech’s HM series of hyperboloid mixers provides optimal mixing tailored for demanding industrial and wastewater treatment applications.

The HM series mixer is available in several installation configurations to fit virtually any existing wastewater treatment facility, avoiding the cost of expensive and time consuming plant retrofits.

Advantages

- Design Advantages. The unique impeller design and mechanical movement allows for steady oxygen transfer rates across a wide range of media from clear water to wastewater. The gentle mixing action keeps solids suspended and prevents sediment from settling at the tank bottom. In addition, the HM series mixer operation reduces unwanted surface aersols which helps control plant odor.

- Cost Advantages. GloTech’s optimal impeller design provices high efficiency mixing and aeration that reduces energy costs delivering mixing across a wide area. The low energy requirements translates directly to cost savings for the end user.

- Maintenance Advantages. Very low maintenance requirements due to simple rugged design with few points of failure. High service life gears and bearings reduces potential downtime. No sensitive maintenance needed for submerged components, with the motor and gearbox easily accessible. Vertical self-centering installation reduces vibration stresses.

Applications

- Equalization pond

- Precipitation tank

- Nitration/de-nitrification basin

- Sequencing batch reactor

Popular Wastewater FAQ

What are Aerator Propellers and how do they work?

Aerator Propellers are devices designed to enhance the oxygenation and mixing processes in wastewater treatment systems. They work by creating a high-speed rotational movement that facilitates the transfer of oxygen into the water, promoting the biological processes necessary for effective treatment.

What are Aerator Discharge Cones used for?

Aerator Discharge Cones are used to distribute the aerated water evenly throughout the treatment system. They help reduce dead zones, ensuring that the oxygen-rich water reaches all parts of the system, thereby improving overall treatment efficiency.

What materials are used in the construction of your aeration products?

Our Aerator Propellers and Aerator Discharge Cones are constructed using high-grade, corrosion-resistant materials to ensure durability and long-lasting performance, even in harsh wastewater treatment environments.

Can these products be customized to fit my specific needs?

Yes, at GloTech, we understand that every wastewater treatment facility has unique requirements. Our team of experts is ready to work with you to tailor solutions for your specific needs.